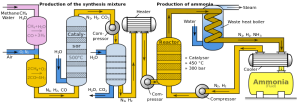

1. Firstly, Nitrogen and Hydrogen (the raw materials), are scrubbed, or cleaned,

to remove any impurities.

2. The mixture of Hydrogen and Nitrogen is compressed, until the pressure reaches

200 atmospheres.

3. The compressed gases now flow to the converter. In the converter, beds of iron

are kept at 450 degrees celcius. Iron is used as a catalyst, since this is a reversible

reaction. Iron forces the reaction to the right, creating ammonia. Only 15 % of the total mixture forms

ammonia.

4. The mixture is then forced into a cooler. Ammonia condenses to a liquid, forming

at the bottom of the cooler, but the rest of gases are recycled to attempt to form more ammonia.

5. The liquid ammonia is collected.

Here is the symbol equation for the reaction: N2 (g) + 3H2 (g) = 2NH3 (g)

A very useful diagram, perhaps to understand the process a bit better!

The raw materials, Nitrogen and Hydrogen, are extracted from different sources. Nitrogen is

extracted from the air. Burning hydrogen in the air removes the oxygen leaving almost pure

Nitrogen. Hydrogen, however, is made by combining methane and steam, forming hydrogen.

As mentioned above, the reaction forming ammonia is a reversible reaction. This means: "Reactions

that do not go to completion and occur in both the forward and reverse direction". In other words,

if not mainted constantly, the reaction would keep reversing for ever. Therefore, the pressure,

temperature and catalyst play a key role in the reaction. Although this reversible reaction favours

lower temperatures, iron (the catalyst) needs at least 400 degrees celcius. The pressure levels are

then what force the equilibrium to produce more product. The iron lowers the activation energy of the

nitrogen and hydrogen, making the formation of ammonia easier. Without the iron, the equilibrium would

not be shifted. However, the reaction would go at such a slow rate, it would be silly to even attempt

the reaction.